Components for oil lubrication / chain lubrication

How can the service life of a chain be extended? Through lubrication, of course! It is not of decisive importance how loaded a chain actually is…

Every chain is subject to a certain load which, in combination with the friction resulting from the chain movement, leads to wear on the moving chain elements. Simple roller chains are not very expensive to purchase in themselves, but chains that have been lengthened considerably cause additional wear on each chain sprocket, resulting in costs for mostly important components that have to be purchased as expensive spare parts from the machine manufacturer. By far the highest cost factor, however, is machine downtime and the cost of repairing/replacing worn parts. These working hours and the resources tied up in maintenance personnel should be the focus of the cost-benefit analysis.

An automatic chain lubrication system always pays off when taken seriously!

What systems are available?

At this point, we divide the “Chain lubrication” field into the following areas: lubricator, lubricating oil line and applicator.

Applicators for lubricating oil

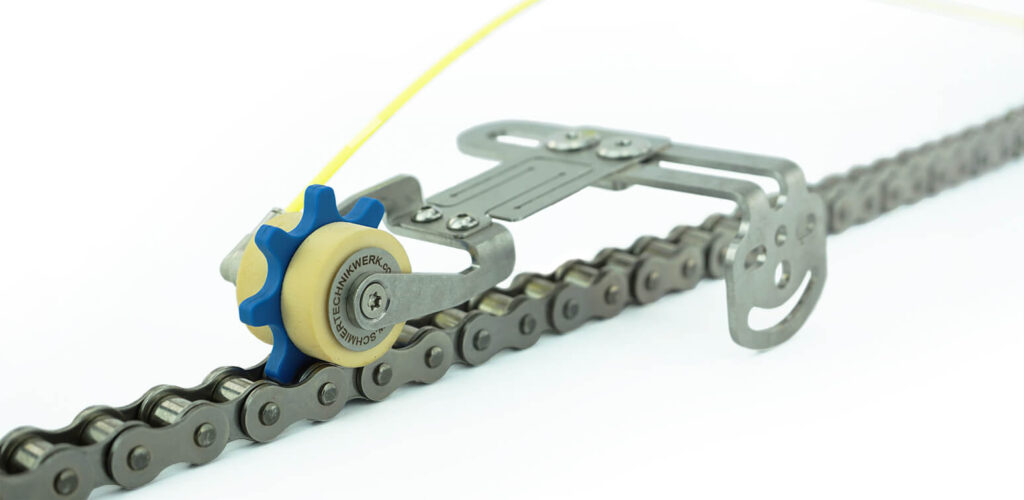

Standard chain lubrication pinion

Chain lubrication pinion with

PU foam applicator

Impulse chain lubrication sprocket

Stainless steel chain lubrication pinion for use in harsh environments

Lubricating brush

Lubrication brush for chain lubrication

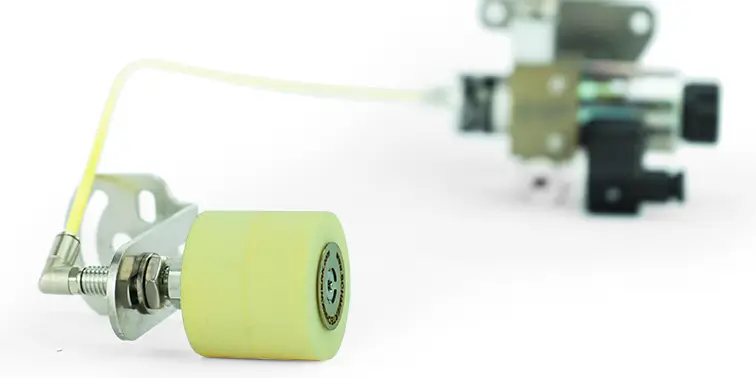

Lubrication rollers / Lubrication rollers

Lubrication rollers for oil lubrication

Accessories for oil lubrication

Universal bracket V2

Mounting bracket or angle bracket for easy attachment and alignment of lubrication scribes or brushes

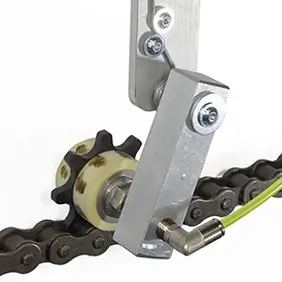

Spring rocker

Spring-loaded mounting bracket for chain lubrication sprockets with a straight axle. For the lubrication of oscillating chains

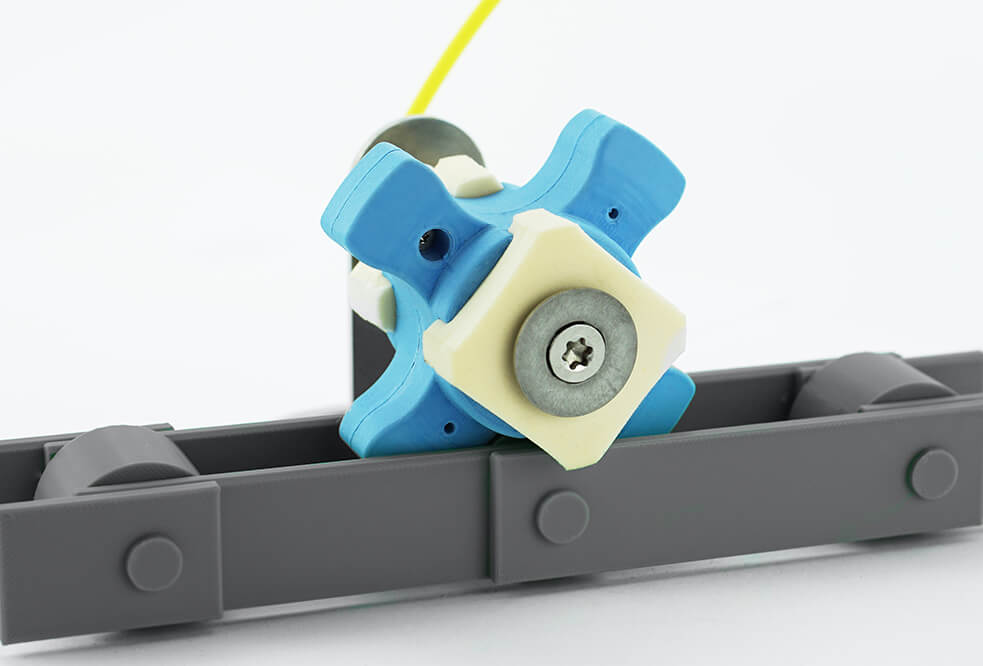

Mounting rail

Mounting rail for lubricant applicators such as chain lubrication pinions, lubrication sprockets or lubrication brushes

Brush holder

Lubricating brush holder or bulkhead fittings for attaching lubricating brushes.

Oil dripper

Single oil dripper for lubrication quantity regulation at a lubrication point

Push-in fittings

Oil-resistant push-in fittings especially for oil lubrication

Standard oil reservoir

TopTank novum: High-quality oil tanks for all lubrication systems made of stainless material

Lubricators

The drip oiler, which has been known for around 150 years, is a classic. A simple oil container, usually made of glass or other transparent plastic materials such as acrylic glass, stores a certain amount of lubricating oil, which is fed to the lubrication points in an adjustable, throttled manner via a needle valve in a hose or pipe. An electric solenoid valve in the outlet of the drip oiler turns it into an automatic lubrication system, so to speak, but with considerable disadvantages.

But first the advantages: A drip oiler is: Inexpensive to purchase, robust and the function is easy to understand.

But the big disadvantage is: An undefined quantity of lubricant somehow runs through a drip oiler to the point to be lubricated. Apart from the fact that the lubricant quantity can only be quantified very imprecisely and at most through a drop sight window, the lubricant delivery once set varies greatly with the fill level of the container, with the changing viscosity over the temperature and with the lubricant used. As a result, the chain to be lubricated is in principle completely over-lubricated or receives far too little chain lubricating oil. it is virtually impossible to set the correct amount of lubricant.

The digital drip oiler or dosing oiler represents a quantum leap. Lubricators of this type also dispense the lubricant in drop form, but the exact same quantity of a drop (30 mm³) is always ejected via a displacement piston. The quantity dispensed does not vary depending on the fill level of the container or the viscosity or other properties of the chain lubricating oil used. By controlling the DEK30 dosing oiler with a programmable controller or the optionally available DigiTimer, a maximum precise drop dispensing time can be set. This makes it possible to experimentally determine the perfect amount of lubricant for a certain chain length, chain speed, load, degree of contamination, etc. and then document it in an absolutely reproducible manner and also transfer it to other machines.

STW DEK metering oilers can be equipped with up to four lubricant outlets and can be combined with oil reservoir sizes from 0.5 to 10 liters.

Lubricating oil:

Depending on the load, attention should be paid to the selection of a suitable chain lubricating oil. This must be designed for the actual load, which means that a heavily loaded chain also requires a heavy-duty lubricating oil. The chain speed is also important when selecting the lubricating oil and, of course, the temperature.

Irrespective of all the above criteria for the choice of lubricant for chain lubrication, it is important to supply the chain regularly and as continuously as possible with fresh lubricating oil.

The lubrication of chains is an important process in industry and helps to ensure the smooth operation of machines and systems. In a production-oriented environment, chains are constantly in motion and subject to high loads. Without proper lubrication, they can quickly wear out and break, which can lead to breakdowns, loss of production and increased maintenance costs. Regular lubrication of chains can increase the service life of equipment, ultimately leading to improved productivity and profitability. It is therefore important that companies regularly review their lubrication practices and ensure that appropriate lubricants are used to minimize breakdowns.